The Old Station House

The Brief

Middlewich railway station served the salt-producing town of Middlewich in Cheshire between 1868 and 1960. When the station finally closed, the single-storey station house was bought and converted into a small three-bedroom private residence. In April 2021 when Colin Biggins, Managing Director and founder of building firm Project Construction, bought the house, his goal was to expand the property and ensure it was insulated to new-build standards economically.

The Task

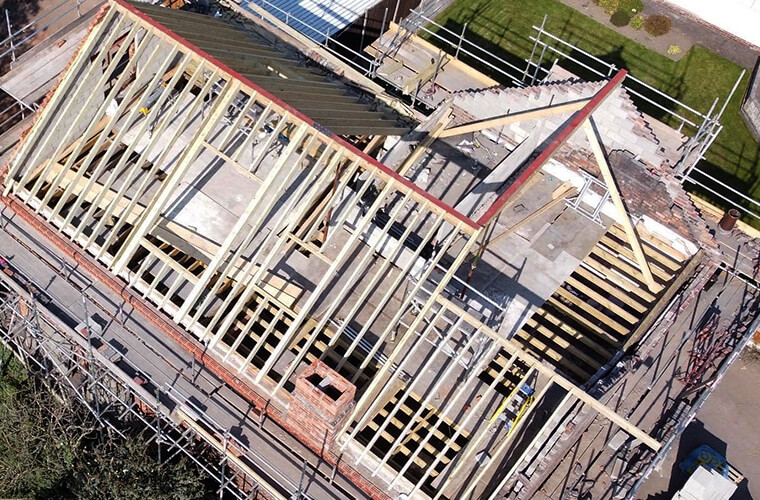

Speed was a key driver for this project but as the construction was extensive, there were Building Regulations requirements to meet. Added to that was Colin’s need to move his young family in while Covid restrictions were in full swing. First Colin removed the roof and added another storey which doubled the size. Now there were five bedrooms, three ensuite, a large family breakfast room and an L-shaped lounge. Aware that energy prices were rising, he wanted to ensure his property would deliver long-term efficiency too. Green Horizon Energy Solutions was engaged to apply spray foam insulation to a depth of 170mm to the pitched roof, and Danny Martin of Wigan-based Aqua Plumbing & Heating was briefed to design the heating system.

The Solution

Colin had already purchased a Hunter Herald 80B 26kW multifuel CH stove, so Danny would need to factor that into the design. To provide the most eco-friendly and cost-effective heating solution, he proposed a thermal store with overheat protection, automatic cross-over controls and a gas combi boiler. On Danny’s instructions World Heat Cylinders supplied a custom-made 300L open-vented slimline cylinder with gravity circuit, mains pressure reverse hot water coil and thermal blending valve to prevent scalding. As the stove uses gravity to move the hot central heating water, the thermal store was installed in a cupboard in the loft bedroom with an external wall, the perfect location for a small plant room. To keep noise to the minimum, Danny selected the Intergas Eco RF36 as it’s virtually silent, but that wasn’t the only reason: “Intergas boilers are unique in their ability to receive pre-heated hot water and, by using an Intergas clip on the pipe temperature sensor, the boiler will only fire up if the water temperature is below 50°C and top up what is needed.” Danny also set the flow temperature on the boiler to around 40°C for heating and 60°C for hot water, to achieve further energy savings. Regular disinfection of any thermal store is important, so once a week the electric immersion heater will increase the thermal store temperature above 60°c to prevent legionella bacteria from growing.

Next Danny had to connect the two separate heat sources, the open-vented stove and the sealed gas boiler which, with an off-the-shelf plate heat exchanger and a low loss header, was easily achieved. Danny said that although the Intergas Eco RF can be used on an open-vented system, as the boiler was located in the loft bedroom there wasn’t the minimum height above it to the feed and expansion tank to prevent it pumping over. The answer was to fit a plate heat exchanger to keep the pressurised boiler circuit and the stove separate; he could have fitted an additional coil to the thermal store and have the boiler heat the store, but this would have meant heating an extra 300L of water instead of just the radiator circuit. It was a good solution and all Danny had to do was alter the pump speed in the boiler settings. With efficiency top of mind, Danny used a large cast iron school radiator for the gravity heat sink and dualredundancy hard-wired Honeywell controls to ensure the stove is always priority.

With the pipe thermostats and cylinder thermostats interlock, all Colin needs to do is light the fire and sit back; the controls will automatically switch the boiler off once the thermal store has reached 40°c and the system will push to the radiators; once the fire has gone out the boiler will cut back in if the room stat is calling for heat.

The entire Old Station House, including its three-metre-high loft rooms which are not heated, are always warm. As for hot water on demand, the Eco RF and the thermal store have got it covered in the most energy-efficient way possible. Job done.

Fast Facts

• Built-in hardware (RF module) enables remote access and control*

• PDHW (additional set up required)

• Vacuum insulation guarantees whisper-quiet operation

• 10m concentric flue and flexi flue options available

• No diverter valve in combis

*Gateway is required for remote access.